Laboratory, Product development

Description

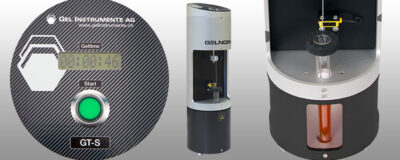

3 Channel System: Control Unit with Temperature Measurement, incl. Software Software

The Gelnorm®– Geltimer PTC-3 evaluates all factors which influence the gel time of reaction resins such as type and quantity of hardener, accelerator, inhibitor, filler, pigments, as well as temperature and moisture. The instrument is extremely easy to operate and normally needs no maintenance.

The principle of measurement of Gelnorm®– Geltimer is simple: A stamper made of aluminium or stainless steel performs an up-down cycle in a test tube filled with resin. When the point of gelation is reached, the test tube is pulled up by the stamper. This stops the clock which was started at the beginning of the experiment and the gel time can be read of.

With the probe temperature system the exothermic reaction can be measured. With the optional temperature controller PTT-3 and electric heating Block GT the sample mixture can be heated up and controlled.

Technical Data

Temperature control for the electrical heating block GT

| Actual value (Pt100) | Range: 0,0 °C … 250,0 °C, adjustable and calibrated |

| Accuracy | ± 0,3% of full scale ± 1 digit |

| Set value | Range: 0,0 °C … 200,0 °C (on request 250,0 °C) |

| Resolution | 0,1 K |

| Load output | Power max. – resistive load: maximum 600 W |

Temperature measurement for the sample

| Sensor | Thermocouple type K (Ni-CrNi), EN 60 584 |

| Connector | Mini connector typ K thermocouples, EN 60 584 |

| Range | 0,0 °C … 400,0 °C |

| Accuracy | ± 1,5°C including cold-junction compensation |

Time

| Display | LCD, 12mm |

| Start button | with status indicator |

| Stop | optical switch |

| Range | up to 99HH: 59MM: 59SS |

| Accuracy | ± 1 second / 2 hours |

Standards

DIN 16 945 Sheet 1, DIN 16 919, DIN EN ISO 9396 and DIN EN 14022 V 5